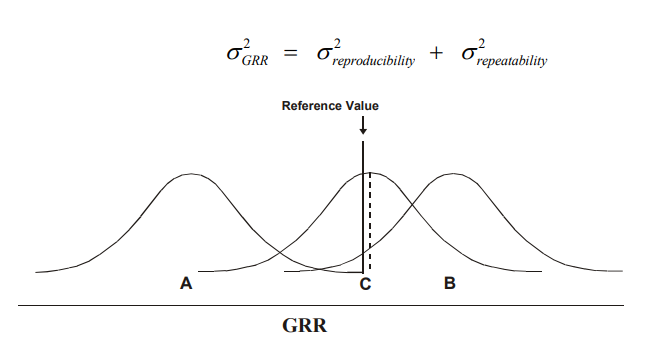

Gage R&R is an estimate of the combined variation of repeatability and reproducibility. Stated another way, GRR is the variance equal to the sum of within-system and between-system variances.

Sensitivity

Sensitivity is the smallest input that results in a detectable (usable) output signal. It is the responsiveness of the measurement system to changes in measured feature. Sensitivity is determined by gage design (discrimination), inherent quality (OEM), in-service maintenance, and the operating condition of the instrument and standard. It is always reported as a unit of measure.

Factors that affect sensitivity include:

Ability to dampen an instrument

Skill of operator

Repeatability of the measuring device

Ability to provide drift free operation in the case of electronic or

pneumatic gages

Conditions under which the instrument is being used such as ambient air, dirt, humidity.

Consistency in GRR

Consistency is the difference in the variation of the measurements taken over time. It may be viewed as repeatability over time.

Factors impacting consistency are special causes of variation such as:

Temperature of parts

Warm up required for electronic equipment

Worn equipment

Uniformity

Uniformity is the difference in variation throughout the operating range of the gage. It may be considered to be the homogeneity (sameness) of the repeatability over size.

Factors impacting uniformity include:

Fixture allows smaller/larger sizes to position differently

Poor readability on the scale

Parallax in reading

source of GRR: Analysis of measurement systems