The capability of a measurement system is an estimate of the combined variation of measurement errors (random and systematic) based on a short-term assessment. Simple capability includes the components of:

Uncorrected bias or linearity

Repeatability and reproducibility (GRR), including short-term consistency

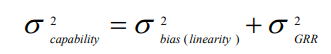

An estimate of measurement capability, therefore, is an expression of the expected error for defined conditions, scope and range of the measurement system (unlike measurement uncertainty, which is an expression of the expected range of error or values associated with a measurement result). The capability expression of combined variation (variance) when the measurement errors are uncorrelated (random and independent) can be quantified as:

There are two essential points to understand and correctly apply measurement capability:

First, an estimate of capability is always associated with a defined scope of measurement – conditions, range and time. For example, to say that the capability of a 25 mm micrometer is 0.1 mm is incomplete without qualifying the scope and range of measurement conditions Again, this is why an error model to define the measurement process is so important. The scope for an estimate of measurement capability could be very specific or a general statement of operation, over a limited portion or entire measurement range. Short-term could mean: the capability over a series of measurement cycles, the time to complete the GRR evaluation, a specified period of production, or time represented by the calibration frequency. A statement of measurement capability need only be as complete as to reasonably replicate the conditions and range of measurement. A documented Control Plan could serve this purpose.

Second, short-term consistency and uniformity (repeatability errors) over the range of measurement are included in a capability estimate. For a simple instrument, such as a 25 mm micrometer, the repeatability over the entire range of measurement using typical, skilled operators is expected to be consistent and uniform. In this example, a capability estimate may include the entire range of measurement for multiple types of features under general conditions. Longer range or more complex measurement systems (i.e., a CMM) may demonstrate measurement errors of (uncorrected) linearity, uniformity, and short term consistency over range or size. Because these errors are correlated they cannot be combined using the simple linear formula above. When (uncorrected) linearity, uniformity or consistency varies significantly over range, the measurement planner and analyst has only two practical choices:

1) Report the maximum (worst case) capability for the entire defined conditions, scope and range of the measurement system,

or

2) Determine and report multiple capability assessments for defined portions of the measurement range (i.e., low, mid, larger range).

source : Analysis of measurement systems