The Variable Gage Study can be performed using a number of differing techniques. for Guidelines for Determining Repeatability and Reproducibility Three acceptable methods will be discussed in detail in this section. These are:

Range method

Average and Range method (including the Control Chart method)

ANOVA method

Except for the Range method, the study data design is very similar for each of these methods. The ANOVA method is preferred because it measures the operator to part interaction gauge error, whereas the Range and the Average and Range methods does not include this variation. As presented, all methods ignore within-part variation in their analyses.

The ANOVA approach can identify appraiser-part interaction but it can also evaluate other sources of variation which is the reason why it was included. Historically, the assumption is made that the interaction is zero, in which case the results of both approaches are equivalent. With that said, the ANOVA approach is preferred because of its flexibility if the user has access to a appropriate computer program. If not, the X bar and R approach is appropriate and can be done manually or via a computer program.

However, the total measurement system includes not only the gage itself and its related bias, repeatability, etc., but also could include the variation of the parts being checked. The determination of how to handle within-part variation needs to be based on a rational understanding of the intended use of the part and the purpose of the measurement.

Finally, all of the techniques in this section are subject to the prerequisite of statistical stability.

Although reproducibility is usually interpreted as appraiser variation, there are situations when this variation is due to other sources of variation. For example, with some in-process measurement systems there are no human appraisers. If all the parts are handled, fixtured and measured by the same equipment, then reproducibility is zero; i.e., only a repeatability study is needed. If, however, multiple fixtures are used, then the reproducibility is the between-fixture variation.

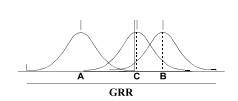

source of Determining Repeatability: Analysis of measurement systems